Take Kelvin Testing to the Next Level

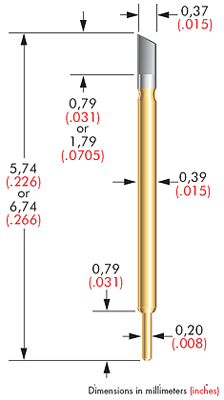

This is an innovative and robust contact technology for making Kelvin contact to 0.5mm pitch QFNs. The contact uses a tip that is angled to one side, matched to an orientation that's flat on the tip. Two such contacts placed in opposition will touch the pad within 0.125mm. And because the tip is offset, the probe diameter is a robust 0.39mm and the load board pad pitch remains 0.5mm.

Plus, the Offset Kelvin contact is uniquely suited to a production environment because of its long life, ease of maintenance and tolerance for device misalignment.

Advantages on Both Sides

Our Offset Kelvin socket offers huge benefits in maintainability and handler setup. The large probes are easy to handle and their high precision makes device alignment effortless.

On the other hand, the Offset Kelvin probe provides a production-worthy solution with affordable loadboards. In fact, even with a shrinking side pitch, the loadboard remains at the standard 0.5mm pitch.

A Long Lasting Solution

When used for fine-pitch Kelvin measurements, this new offset probe technology can measure milliohms of resistance for more than 500,000 cycles on device pad pitches of 0.5mm. The combination of long life and reduced demand for fine features on the board dramatically reduces the cost of Kelvin testing and increases device yields for ultra-miniature, fine-pitch power devices.

A Better, Stronger Tip

The key design advancement of this innovative probe is the beveled offset tip that allows for tighter centers, down to 0.125mm on the device pad.

To increase probe life, the probe tips are constructed from a revolutionary new stainless steel. This stainless steel is 300% harder than the standard gold-plated beryllium copper and it has a natural aversion to solder adhesion. Kelvin Probe

More Accurate testing at a Lower Cost