Battery Probes

Download

Technical data

Beschreibung

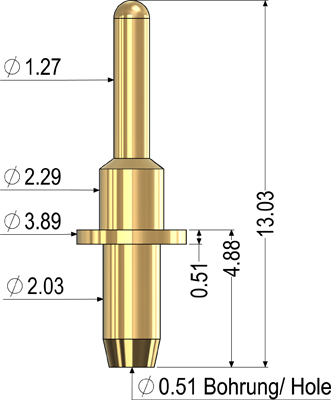

This one-of-a-kind battery probe stands out due to its remarkably high ratio between the heights of the visible plunger and the receptacle. More specific, a portion of 5.61 mm of the total 13.03 mm of the UEBK-11290 are being claimed by the pin shaped plunger head at its relaxed state. The remaining 7.42 mm are being consumed by the receptacle. At the height of 4.37 mm, yonder is equipped with a flange ring with a vertical thickness of 0.51 mm and a total diameter of 3.89 mm. Below that ring, the cylinder has a maximum spread of 2.03 mm, and empties into a concentric aiding hole of a diameter of 0.51 mm via a chamfer at the far bottom of the object. The hole is a means of the galvanization process during production. Above the ring, the cylinder unfolds with a diameter of 2.29 mm, in a rotationally symmetric manner, and equally tapers towards the top end and the following pin-head. Both ends are horizontally flattened, hence creating plane contact-surfaces.

The plunger-head itself consists of a diameter of 1.27 mm and overcomes a spring deflection of “only” 1.52 mm, when being addressed with a recommended force of 1.76 Newton. When compared to its relaxed state, it can be noted that even now, a quite broad horizontal air-corridor remains between absolute top and the receptacle, which can be used to send tempering air-streams through the system to achieve some cooling- or heating-effect. Even with more force applied, the plunger will only dive into the receptacle for a maximum distance of 2.29 mm.

Its dimensions, as well as the materials employed enable the UEBK-11290 to transfer comparably high amounts of electric current of 15 Amperes, while never surpassing a very low contact resistance of less than 10 mΩ. Moreover, the minimum applied grid-size, thus mean distance between parts of the same family lies at 4.45 mm. These characteristics qualify the battery probe to be used in engineering projects, where electrical efficiency and robust design play a role, for example medical-technical devices for ambulances.

The entire plunger consists of a special copper-beryllium-alloy, which was sent through a special hardening-process beforehand. The receptacle is made of a fine nickel-silver-alloy. Both pieces are gold-plated in a final step. The spring, as central element, consists of stainless steel.