Certification ISO 9001

Qualification of Peltier modules concerning their internal resistance

The quality control of thermoelectric modules demands special methods and tools. Different procedures are available but the measuring of AC resistance is very common. An increase of the electrical AC resistance is a typical failure criterion and an indicator of the reliability of a Peltier module.

It can be necessary that the AC resistance of all Peltier modules used in the same application has to be within a tight tolerance. If modules come from different fabrication outputs the requirement of very similar AC resistance must be inspected.

Uwe electronic can provide a wide range of knowledge and experience as well as needed tools to operate those inspections.

Sealing of peltier-modules with silicon or epoxy

RTV Versiegelung

Epoxy Versiegelung

During operation the Peltier module can underrun the dew-point of the surrounding air. In case of continuous operation water condenses out of the air. This humidity can lead to corrosion of the copper inside the module or even to a short circuit. Also water could become a connector between the two sides of the Peltier modules that transports temperature.

To avoid condensation or short circuit to happen Peltier modules can be sealed with different materials. On the one hand there is silicon that is flexible concerning the change in dimension between both sides of the module due to frequent temperature changes. On the other hand there is epoxy that is used frequently in special industries where outgassing must be prevented.

Uwe electronic can offer both ways of sealing.

Assembling cables of Peltier modules

During assembling of modules it can be necessary to individualize i.e. the length of the cables. Uwe electronic is well equipped with experience and tools to fulfil individual needs.

Following services can be provided:

- Extension of cables as well as shortening

- To equip cables with end sleeves, connectors or crimp-contacts

Coating Peltier-Modules with Phase Change Material

An important fact for efficient use of Peltier modules is a very good connection between the element and the object that needs to be cooled or heated. Uwe electronic has much experience due to development and production of the own line of Peltier cooling-aggregates.

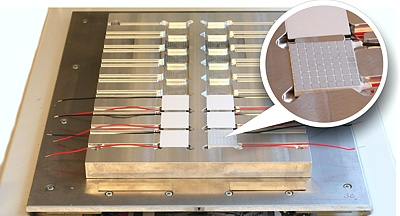

During assembling of Peltier modules a special phase change material (PCM) is being used. The PCM is being placed on the module by using a screen printing technique that takes care of stable coating thickness of 70µm.

The PCM becomes a little softer and sticky at a certain temperature. Therefore it is connecting better with the surface of the object (i.e. heat sink) it is assembled to.

For more information please follow the link:

Uwe electronic offers the coating of Peltier modules with PCM.

Development of custom made solutions in segment of temperature management

Due to our long experience in developing and manufacturing thermoelectric cooling units uwe electronic can also offer individual solutions for special needs of customers.

Variables in the configuration of a thermoelectric cooling unit are the technical data of Peltier modules as well as suitable heat sinks. Solutions with liquid heat sinks are also possible.

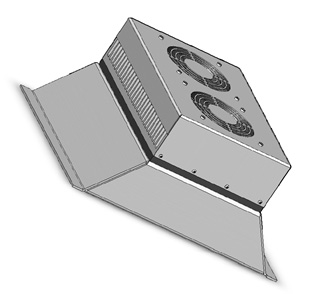

Customized solutions of cooling aggregates and qualification of cooling power

Uwe electronic can offer a wide range of different cooling aggregates. For a lot of types of these aggregates exists the possibility of optional adjustments. That could be for example the performance of fans and their individual air flow rate or the so called “low-noise” technique for units that are qualified for usage in laboratories. Furthermore fences against dust and filters could be necessary as well as special IP class fans can be set up.

Adjustments of the housing or the heat sink are also possible. In case of room being a limiting factor an extension of the housing can be assembled to the cooling unit that results in the cooling unit doesn´t extent into the electrical cabinet any more.

In the segment of “air to surface” cooling aggregates customized cooling plates can be assembled. Therefore the number of plates can be reduced and due to weight reduction temperature settings will be reached faster and more efficiently.

Due to above mentioned customisation it can be necessary to proof the cooling performance of an aggregate. Uwe electronic is well equipped to measure all relevant details and provide a performance test report.

Preprogramming of temperature controller

Uwe electronic offers a diversity of temperature controller. Some of these controllers have many different and complex functions. This requires a time-intensive training to be able to put settings correctly. Therefore we offer the delivery of those complex temperature controller already set according to our customer´s needs.